Users develop models quickly and easily by taking advantage of Parasolid’s extensive mechanical CAD modeling functions, such as adding, subtracting, intersecting, hollowing, tapering and blending solid geometry.Įngineers can intuitively fashion complex organic shapes with non-uniform rational b-spline (NURBS) surfaces created along user-defined guide curves or automatically fitted between existing surfaces. At the same time, the modeling tools need to be intuitive enough for design engineers to master quickly and easily.Īltair selected the Parasolid® software geometric modeler, part of the Xcelerator™ portfolio of solutions and services from Siemens Digital Industries Software, because it offers Altair Inspire™ users the widest array of 3D modeling capabilities available. Mix-and-match 3D modeling in a single intuitive applicationĪltair recognized that a leading simulation-driven design application needs to offer a comprehensive geometric modeler to capture the diversity of form in manufactured products across a broad range of industries, and the range of preferred methods used in their design.

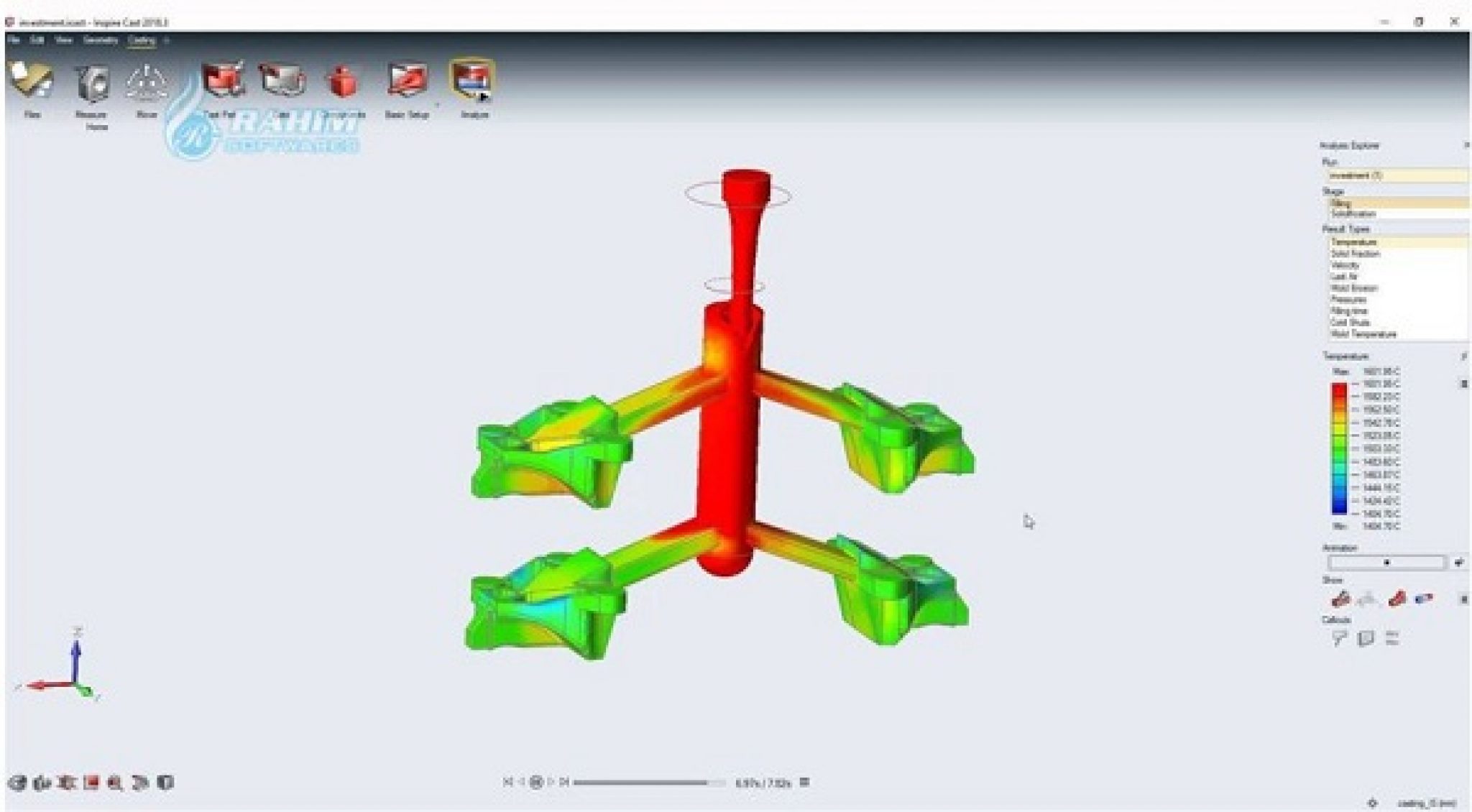

Virtual testing, validation, correction and optimization of designs can be easily performed through a five-step setup workflow to evaluate molded foam part manufacturability, mitigating common manufacturing defects caused by shrinkage and porosity long before a mold is made.Īltair offers a comprehensive set of solutions to develop innovative, manufacturable products faster from the initial part design and understanding the entire molding process, to efficiently analyzing and optimizing the performance of complex parts.Provided customers a sophisticated, integrated 2D sketcherĪltair’s comprehensive, openarchitecture solutions for data analytics, simulation, and high-performance computing (HPC) enable design and optimization for high-performance, innovative and sustainable products and processes in an increasingly connected world. Placing simulation in the hands of designers and product engineers early in the development cycle enables easy exploration of options that deliver improved products, and reduced scrap and tooling rework costs. Inspire PolyFoam provides a modern integrated approach to streamline design for manufacturing (DfM) of flexible molded foam components and rigid foam panels. Their important attributes like lightweight, adaptable strength per unit weight, and insulation characteristics, as well as their inherently high sustainability make them attractive for an increasingly wide range of industrial and household applications. Rigid and flexible polyurethane foams, also known as cellular or expanded polymers, surround us. Altair® Inspire™ PolyFoam Polyurethane Foam Simulation

0 kommentar(er)

0 kommentar(er)